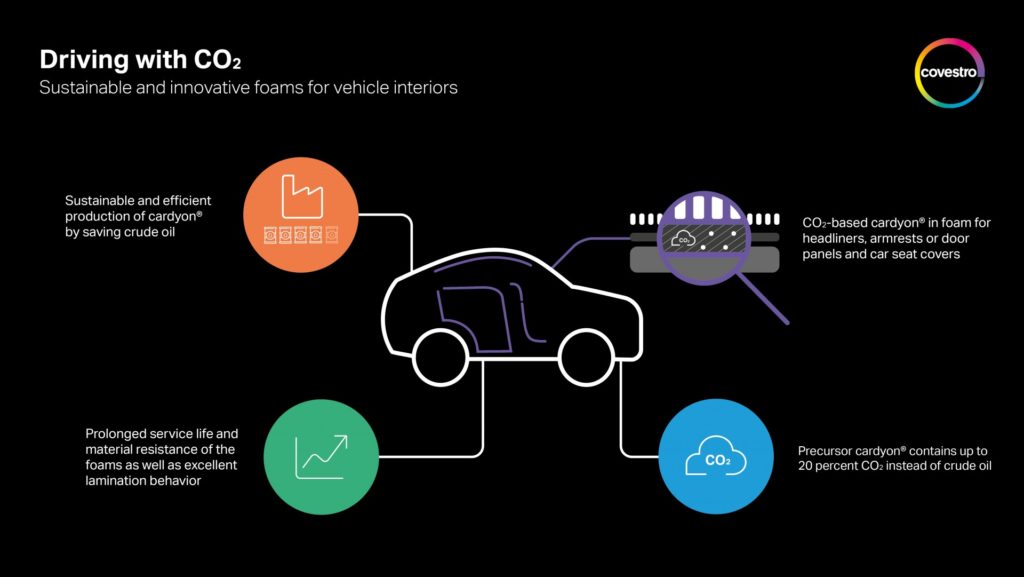

According to polymer specialist Covestro, foams for the automotive industry can now be produced partly using carbon dioxide instead of fossil-based raw materials such as crude oil.

The company says that its precursor material Cardyon, a polyol made up of 20% CO2 , is used for this purpose, and is currently being employed by Swiss company FoamPartner to produce foams for various vehicle interior applications.

“We are now taking another important step towards using carbon dioxide as an alternative raw material in the chemical industry on an even broader scale,” commented Sucheta Govil, chief commercial officer (CCO) of Covestro. “In doing so, we are accelerating the transformation to a circular economy and supporting our positive momentum for growth in recent weeks.”

FoamPartner says it will launch a new product series under the name OBoNature, where theCO2 –based foams will be laminated with a textile. These materials will primarily be targeted for use in headliners, but also in door panels and armrests, as well as in car seat covers.

In addition to their resource-conserving production method, the foams are characterized by a longer service life and increased wear resistance compared with traditional materials, the company says. Moreover, thanks to their optimized lamination behavior, they can be processed in reduced material thickness while at the same time enabling faster laminating processes. This saves both material and manufacturing costs.