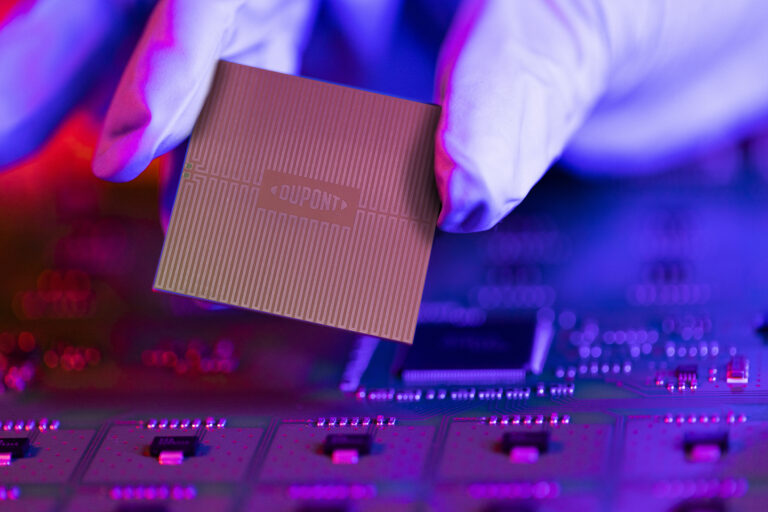

Chemicals company DuPont has introduced the Pyralux ML Series, an addition to its Pyralux laminates designed specifically for flexible and rigid-flex printed circuit boards (PCBs). Designed for “optimal thermal management”, this new series is suitable for a range of applications, including electric vehicles (EVs), aerospace, defense, artificial intelligence-related (AI) networking and other electronic devices.

For complex circuits on both rigid and flexible substrates, laminates play an important role in automotive electronics. The Pyralux ML laminates excel in thermal management, offering optimized performance for flexible printed circuits, sensors, heaters and thermocouples used in high-reliability automotive applications.

Unlike other Pyralux products, the Pyralux ML laminate incorporates metal alloys like copper-nickel (CuNi), combined with Kapton all-polyimide dielectric technology. These alloys provide essential thermal resistance, thermal conductivity, resistivity, and thermoelectric properties, enhancing heat transfer and heat output.

Available in various dielectric and foil types, thicknesses and metal constructions, Pyralux ML laminates offer flexibility and compatibility with conventional circuit fabrication. This versatility makes them an excellent choice for OEMs, designers and fabricators seeking innovative thermal management solutions for automotive interiors.

DuPont Electronics & Industrial is strategically rolling out Pyralux ML double-side clads in sheet form, offering automotive industry stakeholders access to cutting-edge thermal management technology for next-generation automotive electronics.