Mitsui Chemicals of Japan has developed an environmentally friendly grade of its Milastomer product line by using a recycled polyolefin as a principal component of the thermoplastic elastomer. Samples of the new grade are already being sent out to customers. By switching the polyolefin component to a recycled material, the company states it has been able to reduce the product’s CO2 emissions and overall burden on the environment without any loss of performance compared with the original formulation.

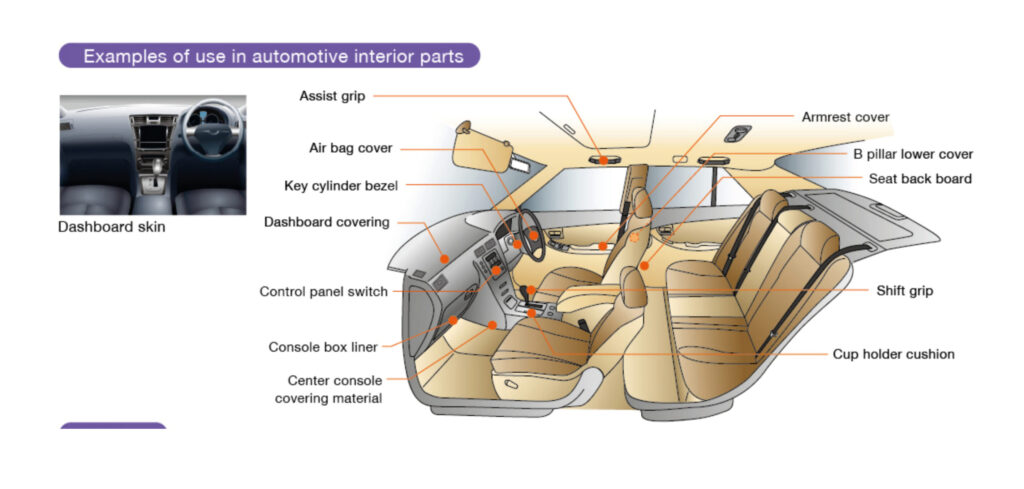

A flexible plastic available in a wide range of hardness grades, Milastomer offers high heat resistance, light weight and low density when compared to other flexible resins. Its principal components are rubber and a polyolefin or other such plastic material. It is currently primarily used in automotive applications such as engine and interior parts and is also used by the construction industry. By adding the Milastomer Eco Series to the product range, Mitsui Chemicals says it hopes not only to offer an environmentally friendly option for use in these existing areas, but also to step up the development of new applications for the material.