Hexpol, a specialist in polymer compounding, says it has expanded its range of thermoplastic elastomer (TPE) materials that feature recycled content, noting that its latest Dryflex Circular TPE grades have been tested for odor and emissions performance in automotive interiors.

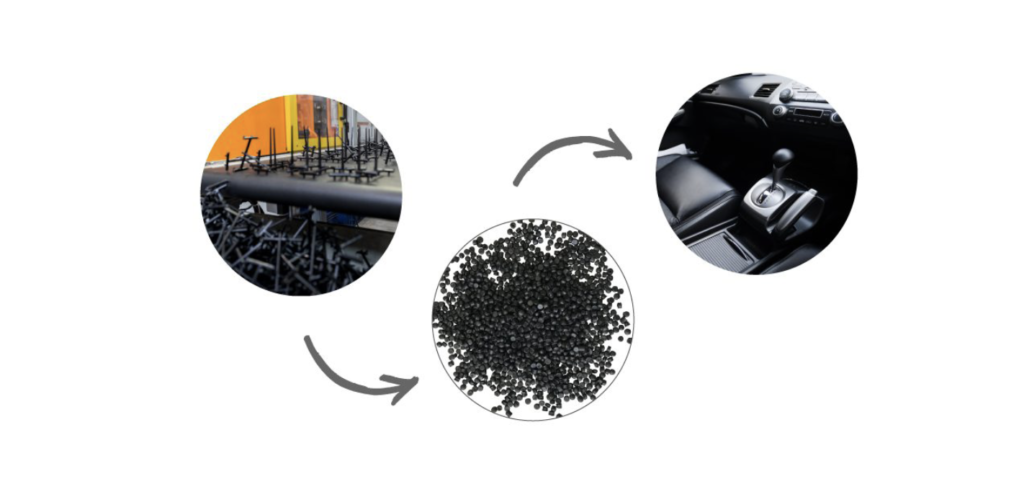

According to the company, TPEs were developed to support the shift from finite fossil-based virgin materials. Recycled polymers from various sources, including post-consumer (PCR) and post-industrial (PIR), are incorporated into the TPEs, which can also be recycled in closed-loop systems at their end of life. Thomas Köppl, group product manager at Hexpol, commented, “Recent developments resulted in us bringing the first TPE with recycled content for automotive interior applications to the market.”

The exact specifications and requirements for odor and VOC vary depending on the application and the OEM. Generally, the material odor must not be disturbing even at higher temperatures (e.g., 80°C). According to Hexpol, using a representative Dryflex Circular TPE grade – consisting of a 65 Shore A material for inlay mats with a recycled content of 20% – showed a very low amount of VOC (60μg/g) and FOG (594μg/g).

The TPE was tested at an external accredited laboratory and shown to have almost no odor (grade 2.0 according to VDA 270, B3). The mechanical properties also fulfill automotive requirements, and coloring is possible. Hexpol says the material is currently being approved by a German car manufacturer.

Köppl added, “With the recent developments of Dryflex Circular TPE, it is now possible to realize high-performance interior applications. Together with our Circular TPE grades for exterior applications and our biobased TPEs, we are supporting automotive suppliers and OEMs to fulfill their targets to increase the use of recycled and renewable materials.”