General Silicones (GS) has announced that automotive components makers are starting to use its Compo-SiL technology. With intelligent cockpits on the rise, featuring ambient lighting, enhanced information displays and functions controlled by virtual buttons and touch sliders, the company notes that the automotive industry is looking for ways to simplify human-vehicle interaction.

According to GS, finding ways to integrate these smart functions into dashboards and surfaces poses a challenge for manufacturers as electronics must be installed within surfaces where they can provide haptic feedback but also be protected against water, chemicals, prolonged exposure to UV radiation from sunlight and big temperature changes.

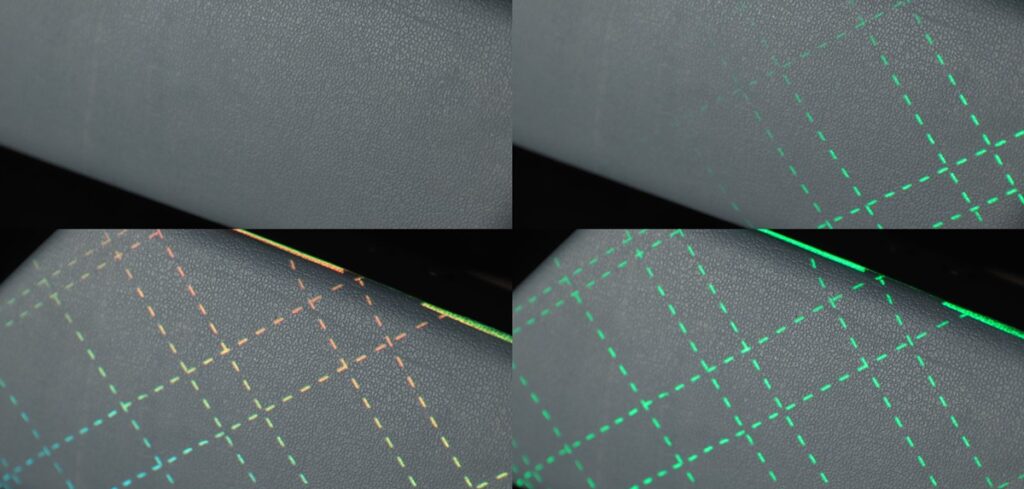

Compo-SiL consists of a silicone rubber that is claimed to have a far higher light transmittance than plastic-based alternatives after dyeing, and the ability to withstand aggressive chemicals. It can be modified to be electrically conductive, enabling customers or manufacturers to integrate control functions for interactive materials. This allows for 3D touch surfaces with intelligent touch sliders, smart buttons and surface illumination.

A patented technology enables Compo-SiL to equip a cured silicone rubber sheet with an ultra-thin polyurethane (PU)-based interface layer. This allows cured Compo-SiL silicone rubber sheet to be bonded to smart surfaces using a standard glue during production.

The PU layer of the Compo-SiL sheets can be printed on using existing digital printing technology, enabling interior and product designers to combine printed design elements with electronic display functions. General Silicones is also able to modify the surface and material properties of its automotive vegan leather to match the feel of natural leather as well as its color and texture.

The silicone rubber sheets from which Compo-SiL is produced are made using an environmentally friendly water-based process, and the material has proved to have a small environmental footprint over its lifecycle.