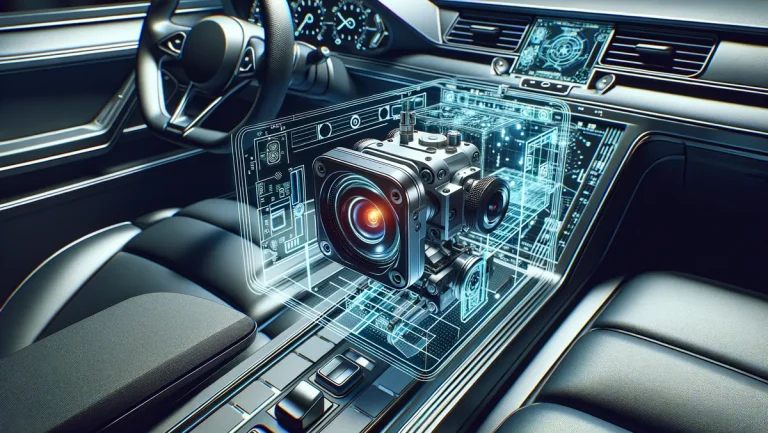

Eyeris Technologies, Omnivision and Leopard Imaging have collaborated on a production reference design to improve safety and comfort in the automobile cabin. The jointly developed reference design integrates Eyeris’s advanced monocular 3D sensing AI software algorithm into Leopard Imaging’s 5MP backside illuminated (BSI) global shutter (GS) camera, which uses Omnivision’s OX05B image sensor and OAX4600 image signal processor (ISP).

Showcased at CES 2024, the production reference design uses depth-aware in-cabin sensing data. This is done by Eyeris’s monocular 3D sensing AI technology, which enables any 2D image sensor, including the latest RGB-IR sensors, to provide valuable depth-aware whole-cabin sensing including distribution and outage management system (DMS/OMS) data.

In addition to using Omnivision’s OX05B 5MP RGB-IR image sensor, the production reference design also uses Omnivision’s OAX4600 ISP to process Eyeris’s monocular 3D sensing AI data. It also benefits from Leopard Imaging’s camera design-house capabilities.

The companies say that the production reference design is designed to enable auto manufacturers and Tier 1s to achieve faster time-to-market with low integration risk.

Modar Alaoui, founder and CEO of Eyeris, said, “Our partnership with Omnivision and Leopard Imaging offers automotive customers the industry’s most advanced 3D software along with a hardware production reference design kit for in-cabin sensing.”

Paul Wu, staff marketing manager at Omnivision, added, “We are excited to partner with Eyeris and Leopard Imaging on this combined solution, which integrates a unique set of capabilities developed specifically for monocular 3D in-cabin monitoring systems.”

For more on sensors, please click here.