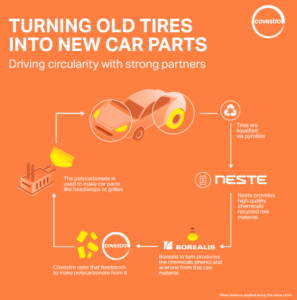

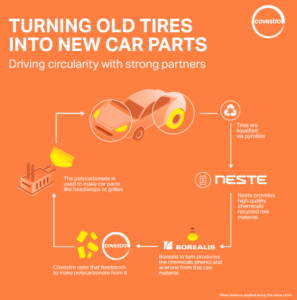

Covestro, Neste and Borealis have signed an agreement to recycle discarded tires into high-quality plastics for the automotive industry. This collaboration aims to enhance circularity in the plastics value chain and automotive applications.

“This project can serve as a blueprint when it comes to establishing circularity in the field of plastics in cars,” explained Jeroen Verhoeven, VP of value chain development for polymers and chemicals at Neste. “It shows how low-quality waste materials can be turned into very high-quality plastics. This is good news for the polymers and automotive industries as well as for the environment.”

The process begins with producer of sustainable fuels Neste converting liquefied discarded tires into high-quality raw materials for polymers and chemicals manufacturing. Borealis, a provide of polyolefin solutions, then processes these raw materials into base chemicals, specifically phenol and acetone, which are supplied to Covestro.

Material company Covestro utilizes these materials to produce high-purity polycarbonates suitable for various automotive parts, such as headlamps and radiator grilles.

The recycled content is attributed via the mass balance approach, for traceability and sustainability throughout the production process, and is certified by ISCC Plus.

The first products from this collaboration are already available, with each partner having produced their initial batch. Beyond polycarbonates, the project may also explore the potential of polyurethanes for automotive interiors. The companies emphasize the importance of scaling up these developments in alignment with future EU regulations, such as the End of Life Vehicles Regulation.