Toray Industries says that it has developed the world’s first 100% bio-based adipic acid, a raw material for nylon 66 (polyamide 66), from sugars derived from inedible biomass. This was achieved using a proprietary synthesis technique combining the company’s microbial fermentation technology and chemical purification technology that harnesses separation membranes.

The company has started to scale up its capabilities in this area and is set to test polymerization of nylon 66, develop production technology, conduct market research and take steps to commercialize applications for this bio-based adipic acid by around 2030.

Pressure to develop eco-friendly nylon 66 has risen in recent years amid a growing awareness of the need to realize a sustainable society. One challenge is that conventional chemical synthesis for producing adipic acid, the raw material of nylon 66, generates a greenhouse gas called dinitrogen monoxide.

Toray was the first in the world to discover microorganisms that produce an adipic acid intermediate from sugars. The company reconfigured metabolic pathways within microorganisms to enhance production efficiency by applying genetic engineering technology, which artificially recombines genes to streamline synthesis in microorganisms. It also employed bioinformatics technologies to design optimal microbial fermentation pathways for synthesis. The quantity of the intermediate synthesized by microorganisms has increased more than 1,000-fold since the initial discovery, and the efficiency of synthesis has improved dramatically.

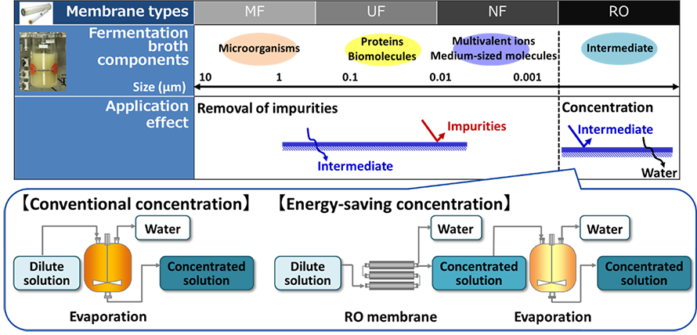

Toray is using reverse osmosis separation membranes to concentrate the intermediate in the purification process. This approach is more energy efficient than other methods that do not use these membranes. The bio-adipic acid production technique is free of dinitrogen monoxide emissions, unlike the manufacturing processes for petroleum-derived adipic acid.